Kredit Co. is a manufacturer of a complete set of mobile shelving, structures and equipment for dynamic storage systems, automated storage systems, as well as non-standard warehouse equipment solutions that meet the special requirements of customers.

The production is fully provided by professional and qualified personnel, as well as the necessary technology and reliable relations with suppliers. The production is carried out in their private closed production facilities with an area of 9.000 m². Typical series of structural parts and groups for warehouse technologies are made on the basis of modular unified parts, complemented by original manufactured elements and included in technological solutions for the customer.

The products of the “KREDIT” meet the most stringent requirements for safety, quality, and technological level, and, at the same time, the most complex requirements for storage, depending on the needs of consumers. Allocated investments for the own development of new products and the continuous process of introducing innovations and investments in production technologies of warehouse equipment are the company’s priority.

- automated industry

- sheet metal

- paper

- food storage

- pharmaceutical companies

- freezers

- forwarders

- machine manufacturing

- steel processing

- archives

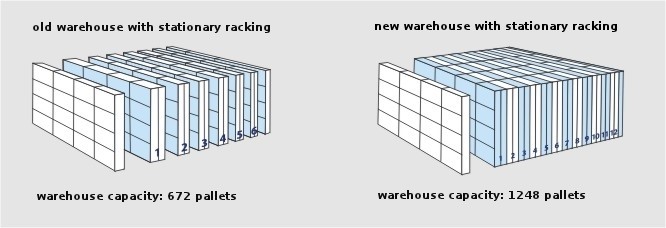

Mobile racks MOBIPAL are a combination of chassis and rack for pallets. They move on tracks built into the floor. The movement is secured by an electrical drive. A control system controls the equipment status and the safety of operation. The use of mobile racks can increase the capacity of the warehouse by up to 100 percent. They are suitable for all types of warehouses that require a maximum storage capacity in a minimum space. The advantage of this system is the possibility of extending storage capacity in the current area, saving the investment cost in building a new warehouse space, and savings operating costs.

Advantages of the rack:

- Saving investment cost while creating new storage space

- Up to 50 % space savings in the current warehouse space

- Up to 100 % increase in the capacity of the current warehouse

- Energy savings in energetically demanding businesses, such as freezer warehouses

- Savings on operating costs Remote control available as an accessory

Mobile racks MOBIKANT consist of chassis and cantilever racks. They move on rails built into the floor. The movement is provided by an electrical drive. A control system controls the equipment status and the safety of operation. The use of mobile racks can increase the capacity of a warehouse by up to 100 percent. They are suitable for all types of warehouses that require a maximum storage capacity in a minimum space. The advantage of this system is the possibility of expanding the storage capacity in the current area, cutting down the investment cost in building a new warehouse space, and savings on operating costs.

Advantages of the rack:

- Cutting down the investment cost in building a new storage space

- Up to 50 % space savings in the current warehouse space

- Up to 100 % increase in the capacity of the current warehouse

- Savings on operating costs

- Remote control as an additional accessory

The MS TOWER, vertical storage system, is designed for sheet material storing. The tower, with an optional ground plan and height, is created from a very robust welded structure, adapted for vertical storage of individual loading units. Containers (loading units) are welded structures, dimensioned according to typical shipping formats and weights of metal sheets.

The extractor, which is a part of the lifting manipulator, performs horizontal displacements of the loading unit from/to the storage location in the tower; the lifting manipulator moves the loading unit vertically from/to the transfer position. The construction of the horizontally moving trolley ensures material lifting above container at operator area, which allows the manipulation of entire package using a forklift.

Manipulation of the individual sheets is usually carried out by vacuum manipulator or a magnet. The double and multi tower system can be equipped with more operator areas, either at front, at back and/or at side machine position (depending on the design of the tower).